A plasticiser is a substance which when added to a material, usually a plastic, makes it flexible, resilient and easier to handle.

Early examples of plasticisers include water to soften clay and oils to plasticise pitch for waterproofing ancient boats. There are more than 300 different types of plasticisers of which about 50-100 are in commercial use. The most commonly used are phthalates and adipates.

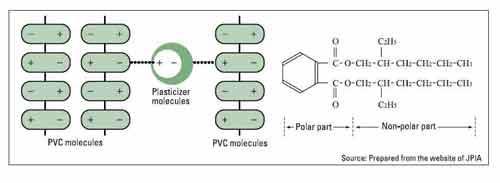

PVC is basically rigid at normal temperature. This is due to the short distances between the molecules since there are strong pulling forces between them (intermolecular forces). When heated, the energies of molecular motions become greater than the intermolecular forces, which widen molecular distances, resulting in softening of the resin.

When plasticizers are added to PVC at this stage, the plasticiser molecules make their way between the PVC molecules and prevent the PVC polymer molecules from coming closer with each other. Consequently the polymer molecules are kept apart even at normal temperature and softness is maintained. This is the role of plasticisers and such process is technically called plasticising.

PVC polymer molecules have positive and negative polarities inside, while plasticiser molecules also have such polar and non-polar parts. The PVC polymer molecules and the plasticizer molecules are electrically attracted to each other, and the non-polar parts widen the distance among the polymer molecules to keep softness.

PVC products which are softened by plasticisers are called soft (flexible) PVC products. In Europe, about 30 % of the total PVC resin production is used for flexible PVC products.

Importantly, plasticisers are not just additives (like pigments or fillers). They conform well to PVC (compatibility) keeping the required softness at minimal quantity (plasticising efficiency) and are major components that determine the physical properties of polymer products and should not easily migrate into air or water (low volatility, low migration).

In Europe, about 30 % of the total PVC resin production is used for flexible PVC products.

In Western Europe about one million tonnes of phthalates are produced each year, of which approximately 900,000 tonnes are used to plasticize PVC. The most common are: diisononyl phthalate (DINP), di-2-ethylhexyl phthalate (DEHP, sometimes also referred to as DOP) and diisodecyl phthalate (DIDP) which have the well balanced properties described above.

These plasticizers account for about 80% of all plasticisers used for PVC. Apart from these three, adipate plasticisers for low temperature resistance and trimellitate plasticisers for heat resistance are used to meet specific requirements.